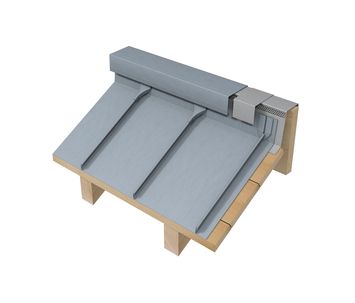

Ks500 1000zip is a standing seam insulated roof panel which gives a secret fix appearance with super fast installation flexibility while maintaining high impact architectural design.

Standing seam roof system details.

Standing seam metal roof panels.

These pans run parallel to the slope of the roof and are joined to adjacent pans with double locked standing seams.

If you will be installing a standing seam metal roof yourself it is best to buy materials from a local sheet metal roofing supplier as many suppliers have the capability to make your standing seam panels right on a job site.

Furthermore standing seam systems are manufactured from high end steel or aluminum offering years of low maintenance service life.

This was a quick overview of the most common standing seam metal roof installation techniques and details.

The recommended dimensions should be specified from the table below.

If part of your design brief is to reduce noise by a value greater than 44 2db then this can be achieved by simply adding mass to the construction.

2 field lok the pc systems consist of three parts the pan a separate seam or batten and a clip.

Standing seam metal roofing is a concealed fastener roofing system which features vertical or trapezoidal legs with a flat space in between.

Standing seam metal roof systems what is standing seam metal roofing.

The standing seam metal roofing systems from berridge include a wide range of coverage and seam height options.

Standing seam roof systems.

Structural design roof panels.

Available in steel and aluminium.

Features a triple lok design been proven to outperform all roof systems in testing for wind uplift resistance.

Centria s standing seam metal roofs deliver clean sleek lines with a minimum of exposed fasteners for a unique aesthetic effect.

Our typical twin skin standing seam roof with a 0 7mm liner insulation to achieve 0 25 u value and 0 9mm aluminium standing seam will give a sound reduction of 44 2db.

This metal roofing system from mbci is one of the most durable and weather tight roof systems available in the industry.

Standing seam roofing is composed of preformed or field formed pans usually between 14 to 18 inches wide when finished.

These systems feature interlocking seams that connect panels giving the roof a distinct and attractive appearance.

The main idea to remember for standing seam systems is that the fastener is hidden whether the panel is attached to the roof deck using a clip or is directly fastened to the decking material under the vertical leg using a fastener flange.

Standing seam systems can be used for either metal roofing which is the most common or metal walls.